BELSILO HOPPER SILOS (SKS)

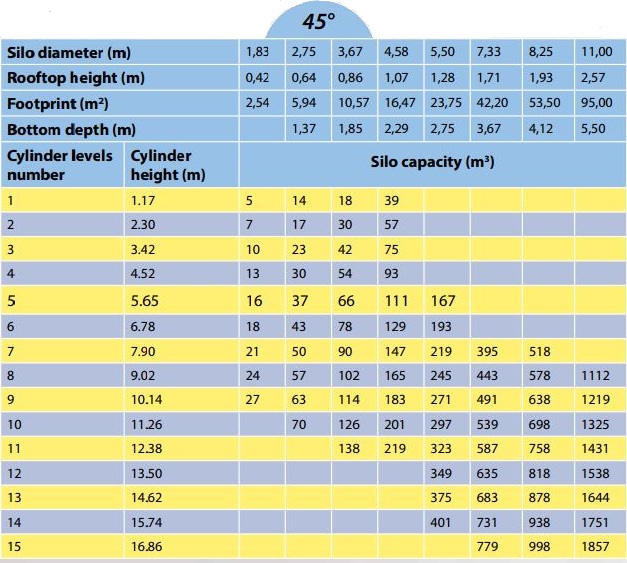

This type of silo is mainly used for short-term storage of grain crops during the cleaning and drying cycle. The storage volume of BelSilo hopper silos varies from 12 to 1500 m3. Cone silos are used both for the operational circulation of raw materials and for long-term storage as part of seed lines. The Silos feeding is carried out by conveyors located on the galleries. Feeding intensity can reach 1200 tons per hour.

BelSilo manufactures Hopper silos with 45º and 60º inclination angles depending on the customer’s request to ensure proper unloading and cleanliness after every unloading. Cone silos with an inclination angle of 45º are used only for handling dry cleaned grain, when loading into auto and railway transport. The 60º cone hopper is used for temporary and long-term storage of non-free-flowing products, such as raw grain, compound feed, malt grinding. Structure of our hoppers have been carefully designed to completely avoid material build-up that can cause product contamination during subsequent use.

Silo outlet hole sizes vary between Ø300 mm and Ø1000 mm. The free height between the outlet and the ground (clearance) can be up to 1 to 2.5 m, depending on the particular installation. The specific calculation of the height is carried out in accordance with the customer’s request.

If necessary and at the request of the customer, a silo vibroactivator can be installed on the cone sheet for shaking and more efficient unloading of difficult-to-flow products.

BelSilo hoppers are mounted on supporting structures. The silo supporting structure consists of columns of hot-dip galvanized sections and is interconnected by panels of rolled profiles. The design guarantees silo high strength and resistance to external influences. Thus, BelSilo silos withstand snow loads up to 240 kg / m², wind pressures up to 160 km / h and seismic loads up to 0.2 g (8 points on a 12-point scale).

SKS BelSilo Hoppers:

- Made of S350GD galvanized steel with Z450 coating corresponding to a zinc reading of 450 g/m2

- Made of high strength corrugated galvanized steel sheets

- Bonded with galvanized outer stiffeners made of high-strength hot-galvanized steel 600 g/m2

- Sheets of the silo body are fastened together by means of bichromated electro-galvanized bolts of strength class 8.8; 10.9, which are equipped with sealed washers;

- The tightness of the joints is ensured by waterproof mastic composite.

The hopper kit includes:

– Roof completed with ventilators, outlets and turbofans;

– Roof ladder with railings;

– Roof hatch;

– Service platform;

– Silo’s body external ladder with fences and areas for rest every 6 m;

– Lower side hatch;

– Rotary type top level sensor;

– Temperature control system with sensors every meter;

– Active silo aeration system

– Electrical and mechanical shutter

The Silo dimensions, volume, number of stiffeners, ground clearance and additional components are selected based on the request and needs of the facility under construction / reconstruction and are agreed with the Customer: tel. (375) 29 3875063, (375) 29 1150635.