FLAT BOTTOM SILOS (SPS)

Flat bottom silos are designed for short-term and long-term storage of cereals, legumes and oilseeds with moisture content up to 14% (rapeseed up to 9%) and weediness up to 3% with active ventilation and constant temperature control. Silos with technological equipment are used both as part of grain cleaning and drying complexes and seed lines, as well as in the form of separate buildings, as part of grain storage facilities with various numbers and locations.

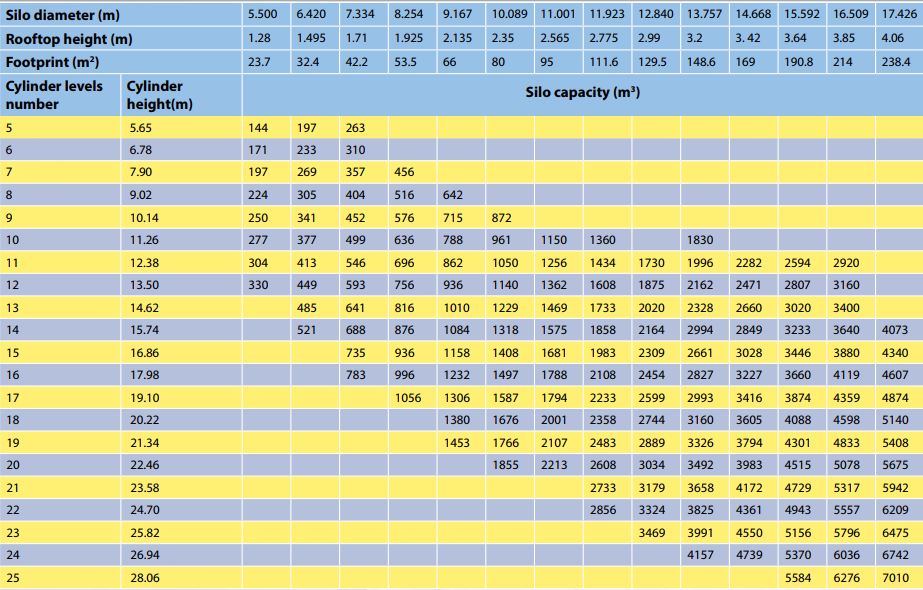

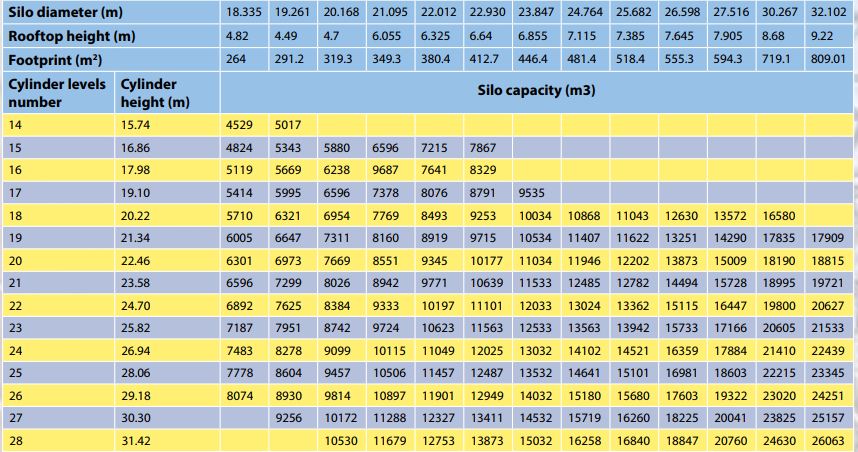

BelSilo produces silos with a diameter vary from 5.5m up to 32m and a capacity of up to 20 thousand m3.

SPS BelSilo Flat Bottom Silos:

- Made of S350GD galvanized steel with Z450 coating corresponding to a zinc reading of 450 g/m2

- Made of high strength corrugated galvanized steel sheets

- Bonded with galvanized outer stiffeners made of high-strength hot-galvanized steel 600 g/m2

- Sheets of the silo body are fastened together by means of bichromated electro-galvanized bolts of strength class 8.8; 10.9, which are equipped with sealed washers;

- The tightness of the joints is ensured by waterproof mastic composite.

The flat bottom silo kit includes:

– Roof completed with ventilators, outlets and turbofans;

– Roof ladder with railings;

– Roof hatch;

– Service platform;

– Silo’s body external ladder with fences and areas for rest every 6 m;

– Lower side hatch;

– Rotary type top level sensor;

– Temperature control system with sensors every meter;

– Sweep auger

– Active aeration system for ventilation channels of the silo concrete base (fan – 2 pcs.)

The advantages of our truss system is made by the principal of frame structure:

- High resistance to vertical and longitudinal loads;

- As a result, the roof is a reliable unifying frame for the entire silo. A powerful, reliable arch is formed around the circumference of the silo every 96 cm. Simplicity and quick assembly of the roof (it is assembled twice as fast as that of competitors).

- A roof inclination angle of 25 degrees reduces the cost of handling equipment and saves power supply by reducing the required power of the geared motor.

- Structures can withstand magnitude 9 earthquakes, 320 kg / m² snow load and 170 km / h wind load.

- Stiffeners staggered arrangement significantly increases the strength of the silo cylinder.

- All holes in the wall sheet are punched in one stamp at the same time after receiving the corrugation, which ensures 100% matching of holes when assembling the silo.

The Silo dimensions, volume, number of stiffeners, ground clearance and additional components are selected based on the request and needs of the facility under construction / reconstruction and are agreed with the Customer: tel. (375) 29 3875063, (375) 29 1150635.