NZ BUCKET ELEVATORS

BelSilo NZ Bucket elevators are designed for vertical transportation of all types of grain crops, rapeseed, corn, legume seeds, granules, biomass and other non-combustible bulk materials with a maximum grain size of no more than 10 mm and an initial moisture content of no more than 30%. Bucket elevators ensure the accuracy and continuity of material transportation at warehouses, feed mills, biomass warehouses, oil and fat plants, etc. They are used in production lines for processing, cleaning, storing grain and mixed feed.

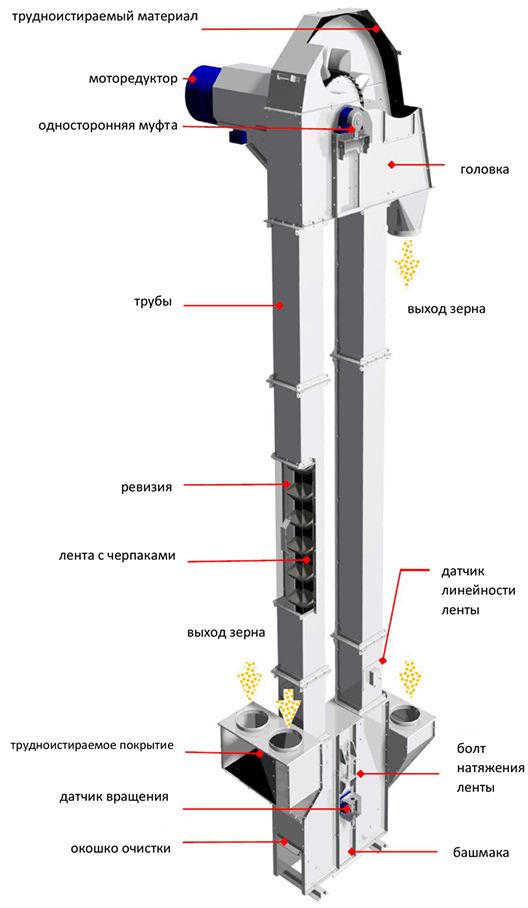

Belsilo NZ Bucket elevator is a vertical structure consisting of two rectangular channels, in which buckets fixed on a belt are moved. Grain is scooped up by buckets at the bottom of the elevator through the loading chute, in the shoe, and is poured out under the action of centrifugal forces in the upper part, which is called as head.

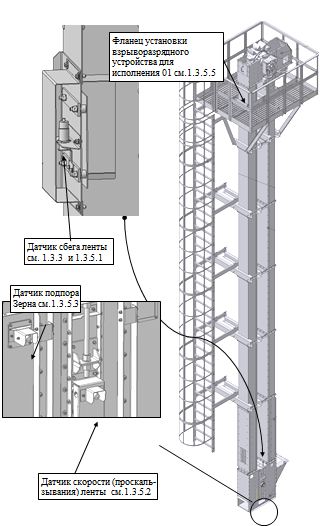

A gear-motor built into the elevator head rotates the upper wheel (pulley), which drives the band with the bucket. A plastic protective plate, consisting of two halves, serves to protect the body from abrasive grain impact. The overrunning clutch is used to prevent the belt from returning with loaded buckets when the engine is shutting off under the emergency. To prevent damage to the elevator during an explosion happening in the head, a flange is provided for connecting an explosive device.

Also in the head design there is a cutter (guide plate). The purpose of the cutter is to prevent grain from being poured into the elevator descending branch pit during the grain pouring from the bucket when turning around the axis of the upper wheel.

In bucket elevators, the direction of the buckets movement coincides with the grain flow (passing grain supply). When unloading, the grain slides over a pad (lining) that protects the head from abrasive wear by the grain. The pad is made of sheet plastic.

Belsilo offers two types of bucket elevators: self-supporting and bucket elevators in supporting metal structures, with a capacity of 20 to 200 t / h and a height of up to 50 meters.

ВelSilo NZ Bucket elevators Advantages:

1. The modular design

- Allows modifying and changing the performance of already purchased equipment.

- Simplifies transportation and installation, switching from right to left version

2. Reliable imported components

3. The inner coating of the elevator parts is lined with a hard-to-wear wear-resistant polymer material

4. Easy access to bearing assemblies and gearbox

- Facilitates and speeds up maintenance

5. Possibility of implementation in ATEX version – for use in closed rooms

Belsilo equips each elevator with the following safety sensors:

1. Band runaway sensor – required to control the stable position of the band

2. Speed control sensor – eliminates band slippage

3. Backflow sensor – designed to prevent the elevator from being blocked by the product

4. Reverse sensor

5. Explosion device

Calculate your effective system productivity and find a system that meets your capacity requirements. For a full list of all specifications, view the table.